[vc_row full_width=”stretch_row_content_no_spaces” css=”.vc_custom_1661448930417{padding-top: 300px !important;padding-bottom: 220px !important;background: #a3a3a3 url(https://steq.com.br/wp-content/uploads/2022/11/Autoclave-Sterilab_Unit2Top_2705-scaled.jpg) !important;}”][vc_column][vc_column_text]

Understand why Autoclave Revamp is a good alternative

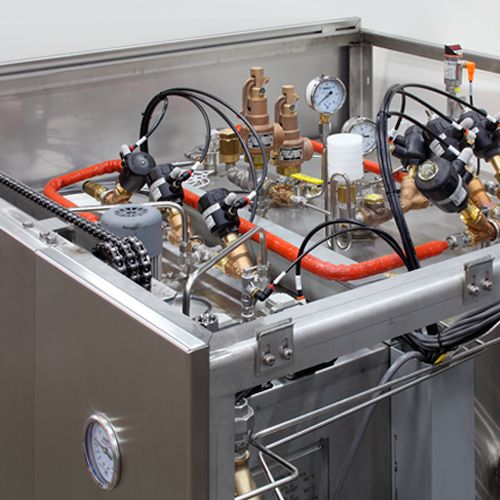

[/vc_column_text][vc_separator color=”sandy_brown” border_width=”3″ el_width=”10″][/vc_column][/vc_row][vc_row css=”.vc_custom_1564073259210{margin-top: 25px !important;margin-bottom: 25px !important;}”][vc_column width=”3/4″][vc_column_text css=”.vc_custom_1669833392662{padding-bottom: 20px !important;}”]In the industry, there is often a need to promote the reconditioning of equipment, such as Autoclaves, in order to ensure its constant efficiency in terms of production capacity, quality and safety. Therefore, the Revamp (or Retrofit) of equipment has become a common and very assertive practice. Understand why.

First of all, what is Revamp?

It is the procedure of refurbishing and modernizing a piece of equipment. In general, it is done as an alternative to the purchase of new equipment, with the aim of optimizing resources. This “reform” can include the replacement of moving parts, recovery and replacement of worn parts and a complete modernization of electronic systems and controls, integrating technology sized for the new functionalities of the equipment.

Why should I think about the Revamp of an Autoclave?

Over the years, the equipment becomes obsolete and the need to increase its production capacity or to give it new functionalities is verified. In this context, the upgrade of an Autoclave is the ideal solution for industries to maintain high productivity without having to bear heavy investments in capital goods and other resources.

Check out some of the technical advantages of Revamp:

- Increased Autoclave Productivity

- Reduced downtime

- Reduced risks to operators

- Upgrading complex systems to user-friendly and simple interfaces

- Integration of the machine into industrial networks and supervisory systems

- Ease of maintenance and supervision of equipment

It’s worth thinking about Autoclave’s Revamp!

If your plant has an Autoclave that has been presenting problems, requiring frequent maintenance and stopping its production, it is a sign that it is time to take action. Therefore, consider revamp as an alternative. Just remember to quote primarily with companies that have the know-how to ensure the technical feasibility of the project as a whole.

To learn more, contact our technical team at contato@steq.com.br or (11) 5186-9400.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_basic_grid post_type=”post” max_items=”3″ element_width=”12″ gap=”15″ item=”958″ grid_id=”vc_gid:1669833552313-84ceeb1c369f5a2c21fee71fd3d4c160-4″ taxonomies=”4, 1, 5, 3″][/vc_column][/vc_row]